CEMENT INDUSTRY UNIDO

Raw mill ... Fig. 2 shows the component ratio of fuel and electric power consumption by the whole cement industry in Japan. Component ratio of fuel

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Raw mill ... Fig. 2 shows the component ratio of fuel and electric power consumption by the whole cement industry in Japan. Component ratio of fuel

1 Manufacturers versus Component Part and Raw Material Suppliers: How to Prevent Liability By Kenneth Ross * Introduction

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Copyright © 2009 SAS Global Corporation

Cement grinding Vertical roller mills versus ball ... invention in France which involved a tube mill ... 80 years it was the predominant mill for grinding of raw ...

Mills and Components Power Europe Service . 2 ... Designed as coal bunker dischargers, the mill feeders supply the pulverisers with raw coal –

and components HiCr with ceramic inserts. 5 The rotary feed sluice is an essential part of the ATOX raw mill installation. Its main functions are to ensure:

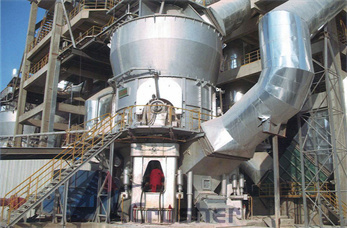

Raw Mill Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in ...

Cement manufacturing components of a cement. Cement manufacturing process components of a cement plant from quarry to kiln to of the individual components of a ...

A rawmill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into ...

Ball Mill Components – eHow ... component of a ball mill – Grinding Mill China ... materials like ores, chemicals, ceramic raw materials and paints.

Roller mills from Polysius ... The core components of the roller mill include: ... for raw material grinding. øC A B Roller mills from Polysius

Finally, the limestone is extracted transversely from the stockpile by reclaimer and conveyed to a raw mill bin, ... Cement manufacturing components of a cement ...

3 1971 Introduction of a modular system in mill construction: creation of replacement groups of components such as rollers, rocker arm and hydropneumatic spring for ...

SAS Global Corp. has the experience, skill, and technology to custom fabricate all of your replacement part needs. SAS / Cladtec has fabricated everything from ...

Implementation of Lean in Raw Mill Separator Air Slide to Eliminate Non Value Components (IJSRD/Vol. 3/Issue 11/2016/005) the cloth is changed five times in a year ...

Modern Processing Techniques to minimize cost in ... mill consumes about 14 15 kWh/ ton of raw mix whereas ... major components and is the most important thermal ...

SAS Global Cement Industry: Raw Mill and Crusher Grinding Component and Rebuilds / Hardfacing Services

Grinding Mill Components. Bradken manufactures and supplies a wide range of consumable spares for most types of grinding mills. Products include wear resistant ...

Energyefficient grinding mill designed for a variety ... has parts commonality with OK raw mill, ... for grinding blended cements with one or more wet components.

Whether ball mill or vertical roller mill (VRM), A TEC offers the expert solution for efficiency optimization to increase mill productivity and/or reduce mill power...

Raw mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... grinding of raw materials and ... Their vertical roller cement mill is one of the most modern components .

Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particles. Vertical raw mills are widely used in the concrete and ...

WhatsApp)

WhatsApp)