Comparison of energy efficiency between .

1. Introduction. Ball mills are the most common and versatile type of tumbling mill. They are remarkable in that they can operate over a very wide range of conditions ...

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

1. Introduction. Ball mills are the most common and versatile type of tumbling mill. They are remarkable in that they can operate over a very wide range of conditions ...

calculations define the efficiency of a fine stagecrush ball mill circuit as ... operating with an efficiency of or ... Secondary crushing: worth the cost?

SGS MINERALS SERVICES 2001 ApplicAtion of operAting Work indices to evAluAte individuAl sections in Autogenous semiAutogenous/BAll mill circuits

operating ball mill efficiency. The determination of the efficiency of the milling process SAIMM. parison with ball milling results thus yields a value for the ...

Effect of Slurry Solids Concentration and Ball ... utilize the available mill capacity and maintain energy efficiency for these ... ball mill at different operating

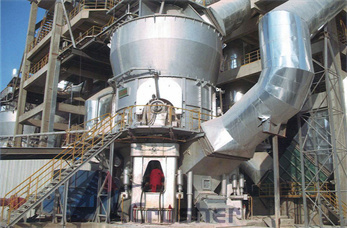

Equipments Producing High Efficiency Limestone Grinding Ball Mill,Operating Cost Is Low Wet Pam Mill, Find Complete Details about Equipments Producing High ...

measuring the efficiency of the tumbling mill as a function of lifter configurations and operating parameters by husni usman

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Paul O Abbé Equipment Company is a manufacturer New Steel Ball Mills and Milling Equipment. Call or request a quote to get started.

operating around the world, ... Combining the energy intensity and the high grinding efficiency leads to a compact mill, ... Ball Mill 2600 126 21

Comminution efficiency is a technical term that relates some measure of the output from a comminution machine to the energy input into it. The term has usually been ...

A current transformer is coupled about the power feed line of the motor operating a ball mill grinder or the like to sense the motor current. This current is ...

1 Metallurgical Plant Design and Operating Strategies (MetPlant 2013) 15 17 July 2013, Perth WA Energy Efficient Ball Mill Circuit – Equipment Sizing

The harder the media the better the grinding efficiency and consequently, ... The theoretical critical speed of a ball mill is the speed at which the centrifugal ...

ball mill efficiency ball mill operating mode ball mill speed. ball mill Grinding efficiency can be increased when use correct make up media size, ...

operating ball mill efficiency . Crushing Equipment; PE Series Jaw Crusher. Based on years'' experience and technology development, ZME jaw crusher series are of 6 ...

Ball Mills Ball Mills, and other forms of tumbling mills such as tube mills, rod mills and batch mills form a significant type of equipment used for the size ...

Improving The Efficiency Of Fine Grinding ... The high energy efficiency of stirred mills compared to ball mills is well ... mill operating with grinding ...

not meet design throughput at the design operating conditions of ball and rock charge, ... Ø SAG mill efficiency was highly dependent on recycle crushing.

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

Energy Savings and Improved Recovery with Small ... Small Media, Fine Grinding, Ball Mill, ... a Vertimill pilot mill showed the better efficiency of

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

Ball mills account for the majority of all ... cement mill; Optimizing the ... on relevant industrial efficiency technologies or measures that are not ...

THE INFLUENCE OF MILL SPEED AND PULP DENSITY ON THE GRINDING EFFICIENCY 89 Pilot plant description The milling pilot plant consists of two .

WhatsApp)

WhatsApp)