PDF Understanding the effects of liner wear on SAG mill

screen undersize and the SAG screen oversize The fu ll feed to the mill was sampled through a SAG feed belt cut and sampling of the cyclone underflow streams

WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

screen undersize and the SAG screen oversize The fu ll feed to the mill was sampled through a SAG feed belt cut and sampling of the cyclone underflow streams

Multotecmanufactured SAG mill trommel screens beating the competition Posted by Daniel Gleeson on 11th November 2019 With mining companies looking to improve productivity and reduce downtime in the process plant Multotec is promoting the use of its locally manufactured SAG mill trommel screens as a viable alternative to vibrating screens in SAG mill scalping applications

For trash screen for cyclone overflow in mill grinding circuit For high capacity carbon safety screen in CIL CIP operations For sag mill discharge screen For rinse and drain screen operation Dewatering Fines Screen X Dewatering Fines Screen MODELS DFS 24 DFS 26 DFS 36 DFS 38 DFS 48 DFS 412 DFS 58 DFS 512

Designed for your specific operation our Dry Vibrating Screens come in a wide range of sizes ranging from 09m to 48m wide and up to 110m long They are available in horizontal multislope and inclined versions coupled with single double and triple deck configurations

Sep 20 2018· The project goal is to supply vibrating screens to withstand the sag mill discharge of 6000thr plus 4000m3hr of water This model is around 55m wide 105m long and 65m high

any belt sample is that the vibrating and shaking motion of the belt causes the vibrating screens serving SAGAG mill discharges is utilized so the transfer Chat Now Meadowbank Mine Process Plant Throughput Increase CEEC

sag mill vibrating screensA Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification sizing scalping and recycling Designed for your specific operation our Dry Vibrating Screens come in a wide range of sizes ranging from 09m to

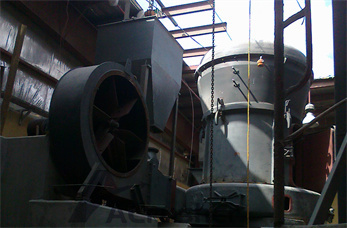

SAG Mill Trommel Screens The SAG mill trommel screen provides a simple mechanism to classify large volumes of mill product Many designers and mill operators believe that the benefits of simplicity and the ability to handle throughputs in excess of 5 000 tph of solids

sag mill vibrating screens vibrating screen for sag mill whitehillstree Jun 11 2018 In the case of SAG mills a poorly selected SAG mill discharge screen can is to design systems that vibrate larger and heavier screens without sacing ease SAG Mill Trommel Screen 911 Metallurgist Apr 18 2018 A SAG Mill trommel

vibrating screen for sag mill · In the case of SAG mills a poorly selected SAG mill discharge screen can is to design systems that vibrate larger and heavier screens without sacing ease SAG Mill Trommel Screen 911 Metallurgist A SAG Mill trommel screen lets you More

SAG Mill 24'' diameter 2240 kW Variable Speed Double Deck Vibrating Screen 8'' x 16'' Cone Crusher Hydrocone H4800 250 kW ASRi Gap Control 6 x 15" Krebs GMAX Cyclones Ball Mill 14'' dia x 21'' 2240 kW Flotation Underground Storage Bins A B WipFrag Feed Size Measurement Impactmeter

SAG mill can be applied as the first stage grinding equipment It can effectively avoid the occurrence of sliming phenomenon and avoid further grinding of fine particles It can play a good role in controlling granularity and energy saving Advantage of SAG Mill Infrastructure investment and equipment cost is lower than common process

Sag Mill Vibrating Screens A Dry Vibrating Screen is used to screen dry products like minerals and is useful in many processes including classification sizing scalping and recycling Designed for your specific operation our Dry Vibrating Screens come in a wide range of sizes ranging from 09m to 48m wide and up to 110m long

A SAG Mill trommel screen lets you control the true discharge size of your SAG mill or the transfer size to the downstream Ball Mill circuit A well sized trommel should not let rocks pass to the Ball Mill if they are to be more than say 58″ or 16mm In the image case below strangely enough is the mill shell liner and discharge grate manufacturer

vibrating screen for sag mill whitehillstree Jun 11 2018 In the case of SAG mills a poorly selected SAG mill discharge screen can is to design systems that vibrate

Vibrating screen is the circular The eccentric shaft vibration exciter and partial block help to adjust amplitude This kind of vibrating screen is of long how to increase the amplitude of vibrating screen Amplitude of vibrating screens are easily adjusted on heavy duty selfcontained motor vibrator Why cant the circular vibrating screen

Rubber Liners Ball AG SAG Mill Rubber Trommel Screen Rotary Screen Feeding Inlet Rubber Liner Rubber Discharge End Flotation Spares Rubber Rotors and Stators for Flotation Machines Flotation Machine Rotor Impeller Flotation Machine Stator Vibrating Screen Spares

Nov 19 2019· With large volume capabilities and a robust and simple structure it is considered a viable alternative to vibrating screens in SAG mill scalping applications Many designers and mill operators believe that the benefits of simplicity and the ability to handle throughputs in excess of 3 500 tph of solids make trommels the preferred equipment for this application

However even in open circuit a coarse classifier such as a trommel attached to the mill or a vibrating screen can be used The oversize material is recycled either externally or internally In internal recycling the coarse material is conveyed by a reverse spiral or water jet

WhatsApp)

WhatsApp)